Salvagnini is a mechanical company founded in Milan in 1963 by Guido Salvagnini for the production of hydraulic energy packages. It operates in the field of deformation machines and laser cutting machines. It also deals with numerical control and machine tool software.

In 1968, Salvagnini entered the sheet metal process automation sector, and then in its early stages. Transferics, a new technology for transferring workpieces from one point to another quickly and accurately, was born and patented.

In 1975, the company moved to its current location and changed its name to Salvagnini Transferica. Two years later, Guido Salvagnini invented and began marketing the first Bender Panel (P4), a computer-controlled programmable machine to bend a sheet of metal on all four sides, flexibly and automatically. At the EMO trade show in Hanover in 1979, Salvagnini caught the attention of the international market, presenting an integrated production line consisting of an S4 puncher and a P4 panel bender.

This marked the birth of the first flexible and automatic sheet metal panel production system, which heralded the concept of “Flexible Manufacturing System” (FMS) that would only be established in the sector several years later.

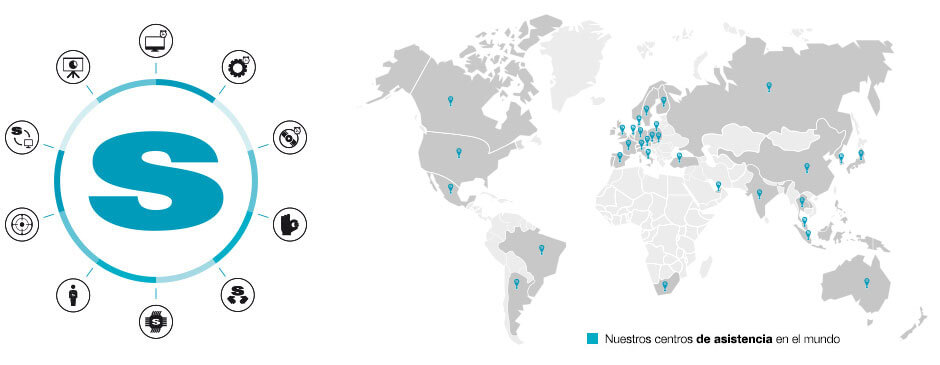

Today Salvagnini now has 5 production facilities and 23 operating companies, with 1,510 employees and a production area of 75,000 m 2. More than 6,000 Salvagnini systems have been sold and installed in 75 different countries worldwide.

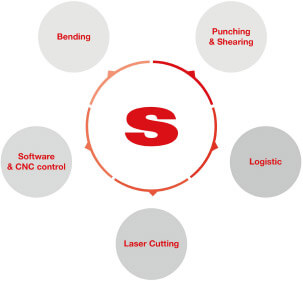

The main services that Salvagnini offers to the sector are:

Software Supplies:

We develop tailor-made programs to constantly improve the performance of your systems. There are tailor-made interfaces for all Salvagnini systems, which are perfectly adapted to specific production requirements.

Mechanical Supplies:

Salvagnini systems evolve over time as well as your production demands. We have developed specific mechanical supplies for each product line capable of satisfying any type of need, optimizing the production and flexibility of your machines and reducing production times in order to make parts completely different or even in different ways.

Hardware Supplies:

We take care of updating the control units of your machines with compatible models that incorporate the most modern management software. In the event of a power outage, we intervene to protect the working data in real time by electrical updates capable of properly shutting down the system without affecting production.

Among other services on Salvagnini’s official website